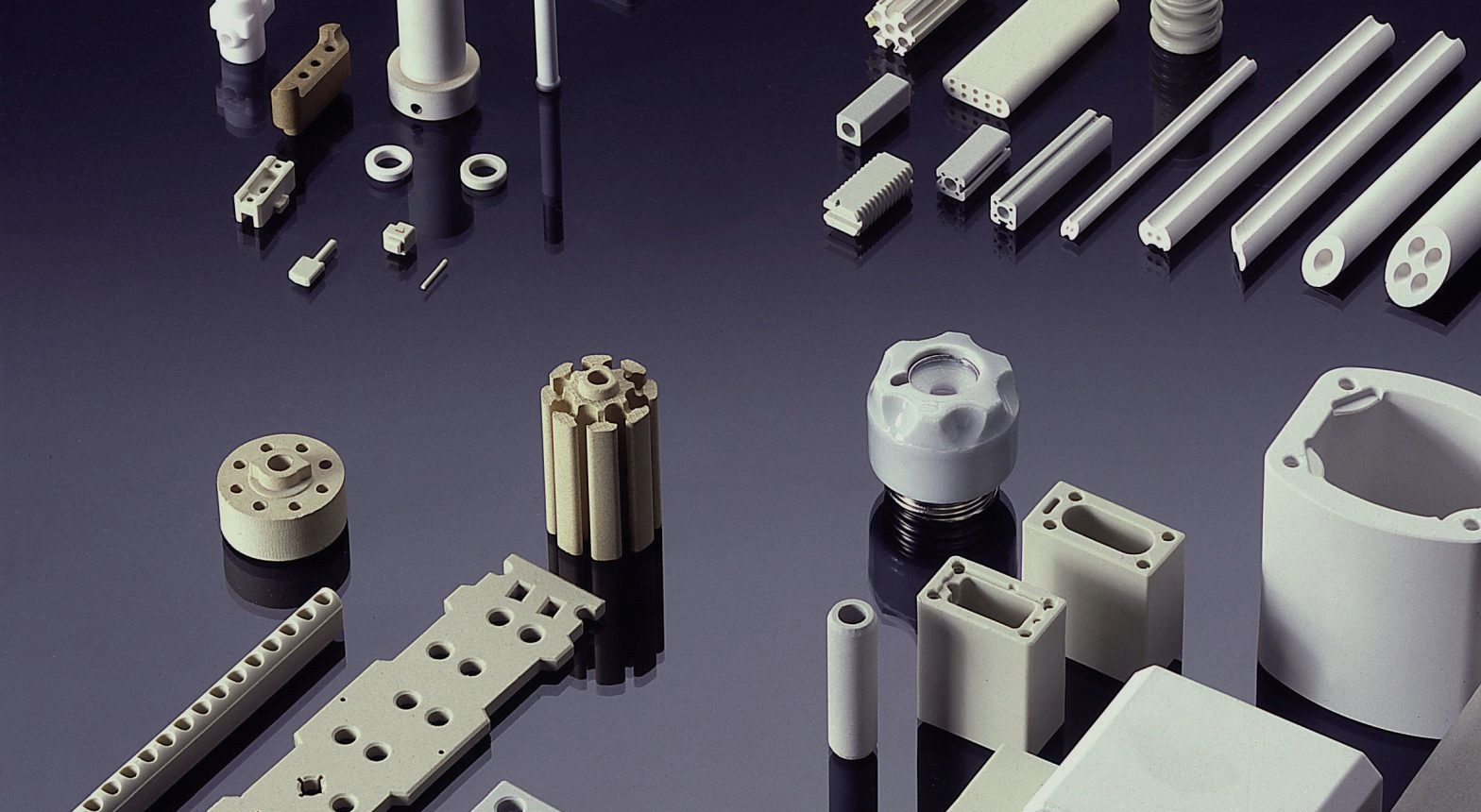

Welding technology

For the right cohesion – Welding technology of the highest quality

Welding pads, loose or customised

-

-

- So-called welding chips or bars

made predominantly of the material cordierite C410 and C520 - Welding and soldering pads

made of alumina C786; honed and polished for high demands - Customised welding pads

are made of welding chips which are stuck on double-sided adhesive tape, and thus customised ready for use in shipbuilding, for example.

- So-called welding chips or bars

-

Welding tubes and sector parts for resistance welding

-

-

- For resistance welding made of the materials cordierite C410 and C520. Also made of aluminium oxide for very high-grade applications, e.g. welding bead supports.

-

Weld studs

-

-

- made of zirconium oxide

- for the most sophisticated applications: made of silicone nitride

- alternatively: ceramic-coated metal parts

-