High temperature heaters

High temperature heaters from Rauschert

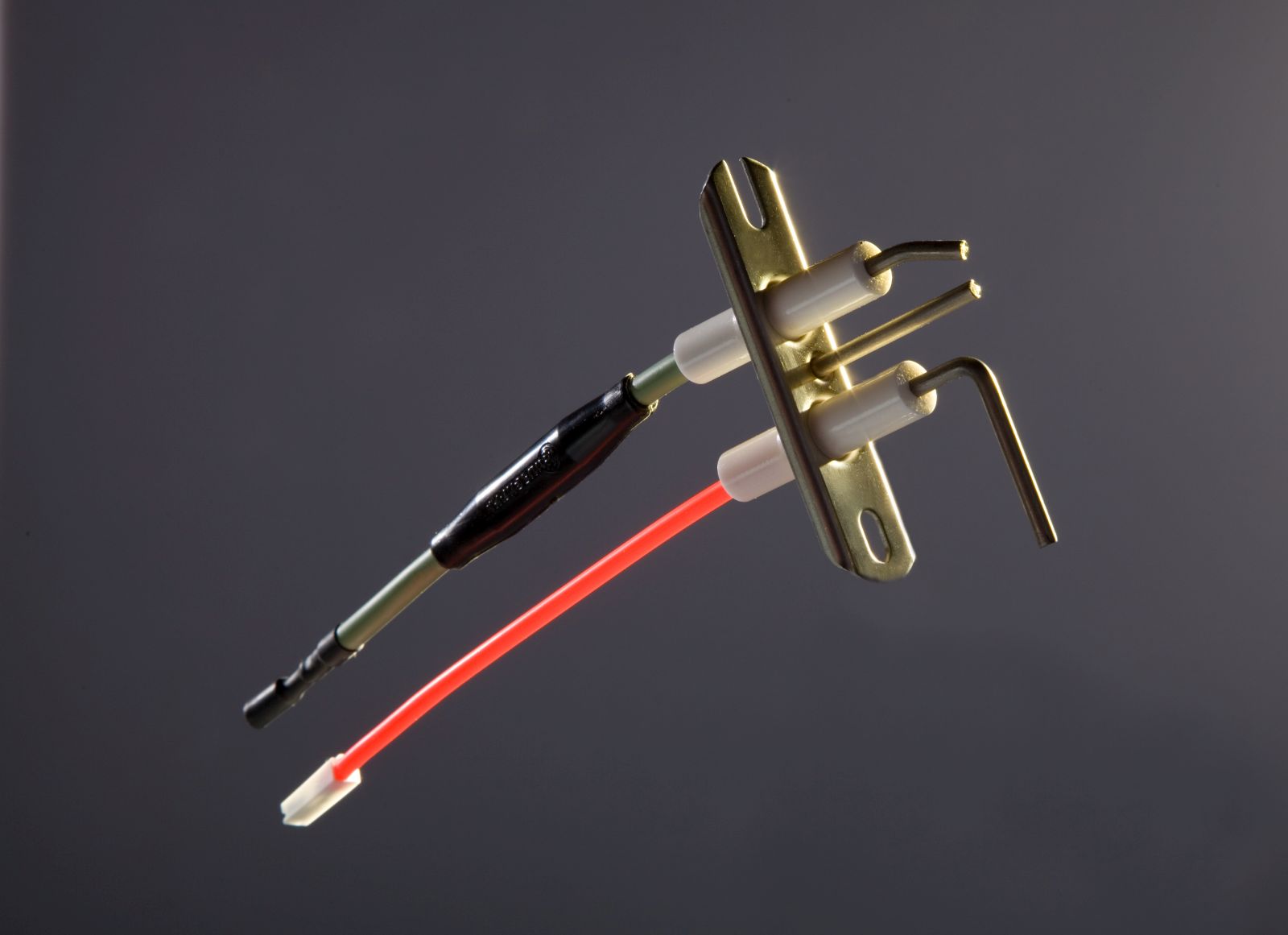

In the production process of the ceramic heating elements, a ceramic film with an imprinted conducting path is linked with the ceramic carrier material via a so-called laminating process. In the subsequent firing process the sintering into a monolithic component takes place.

By integration into the alumina body, the platinum conducting path is protected from the ambient atmosphere and electrically insulated to the in-and outside. Thus, the heating elements are extremely resistant to oxidation and corrosion, durable and robust. Standard heating elements have proofed their durability over more than 100,000 heating cycles (heating and cooling for two minutes each). Due to the compact design, precise heating is possible, specifically where the heat is needed. The ceramic heating elements are deployable in continuous or alternating operation up to 1100 ° C and for a short time up to 1300 ° C. With thin-walled geometries, heating rates of up to 1000 K / min are possible

High temperature heater from Rauschert

High temperature heating elements

Ceramic heaters and ceramic heating elements

A major advantage offered by the platinum conductor path is the linear resistance depending on the temperature. As a result, the heater can simultaneously serve as a temperature sensor and the current operating temperature can be determined at any time. Another advantage is the infinitely variable controllability of the heater temperature via the voltage, from room temperature to the maximum temperature.

In addition to determining the temperature via the resistance of the heating circuit, it is optionally possible to design it with an additional sensor circuit.

Properties & Applications

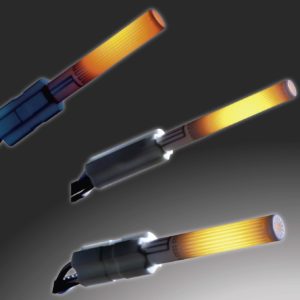

Numerous applications require precise and fast heating. The compact design of the HTH is ideal to fulfill these requirements. With a minimum energy consumption of a few watts, the lightweight components reach 1000 °C in just a few seconds.

Due to the infinitely variable controllability of the ceramic high-temperature heater’s temperature, the application possibilities are manifold. The special strength lies in the achievement of maximum process temperatures of well over 750 °C and up to 1100 °C in continuous operation and briefly up to 1300 ° C. Various types of melting, welding and soldering tasks (soldering iron) can be mastered. The typical standard applications of ceramic heating elements include gas ignition or hot air generation. Further fields of application are the use as heating in special machines or of tools.

Are you looking for a customized solution for laboratory equipment?

The ceramic heater is used in numerous applications of chemical analysis and process technology as a mini furnace or reactor. For this purpose high-purity raw materials as basic material for the heater are crucial. An example is the use of the high-temperature heater in the Mars mission in the “ExoMars Rover“. The heater from Rauschert vaporizes rock samples for analysis purposes so that any existing organic components give hints on traces of life on our neighbouring planet. This example of application shows in particular the exceptional longevity and energy efficiency of our heater under extreme conditions.

This is what we offer